The Celotex & Recessed Downlights Conundrum

Installing recessed downlights into ceiling voids containing thermal insulation has now become a routine practice. Depending on which type of insulation you've got, the installation can range from being easy to do or almost impossible. To comply with Part L of the Building Regulations (Energy Efficiency) you're not supposed to cut around the insulation as this creates drafts and defeats the point of laying the insulation in the first place.

Can you lay insulation over downlights? Let's uncover the truth...

Main Types of Thermal Insulation

There are two main types of thermal insulation with rock wool being the most common type. This is flexible like a rug shown below.

Celotex and Kingspan are two other brands with similar styles that come in a rigid board format:

When you're installing rigid style insulation such as Celotex or Kingspan it must remain vapor proof or it won't be effective. Even cutting into it and covering it with something else such as a loft cap is not recommended.

For Rock Wool Downlight Installations

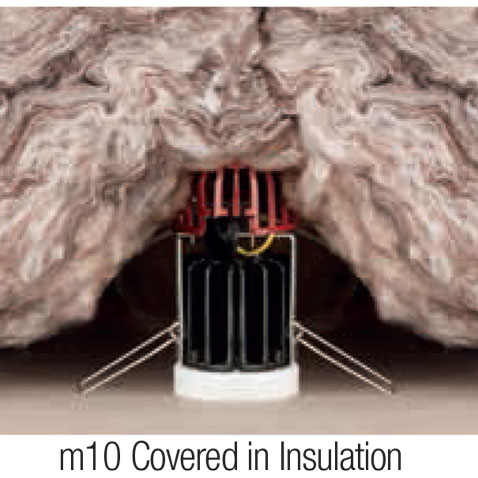

Install purposely designed insulation coverable downlights such as the Aurora Insulation Coverable range which can be found by here. This type of fire rated downlight can be covered directly with insulation as they are specially designed either to work only with cooler running LED lamps. We have a wide selection of insulation coverable downlights to choose from.

Aurora EFD Pro

For existing installations, or if you want to install a different style of downlight; fit a loft cap for downlights or loft cover over any fire rated or non fire rated downlight. You can cut around rock wool style insulation slightly as the the cap or cover acts as a type of barrier itself. The loft covers shown below act like a type of jacket and also allow the lamp (or LED) to ventilate.

For Celotex or Kingspan Downlight Installations

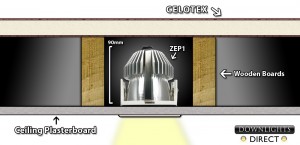

Celotex (the manufacturer) recommend installing wooden battens at the side of the downlight(s) to raise the insulation over the downlight. This is not always practical but this is the recommended practice, see our diagram below:

The wooden boards create a space (or service void) for the downlight to be installed into. The shallower the downlight, the thinner the boards need to be. We have shallow LED downlights available which are all less than 50mm in depth!

Other Downlighting Options

If installing wooden battens is not practical then what about installing surface mount downlights instead of recessed? We offer various styles of surface downlights which don't require any holes to be cut into the ceiling. Integrated LED versions are ultra from 15mm in depth with the Click Inceptor Apto.

Most surface downlights these days have integrated LEDs which is because of their more compact physical size. A GU10 lamp will add around 80mm to the depth of the fitting when you've taken the lamp holder into account, while an integrated LED fitting is around 25mm in depth.

Hope this helps but feel free to contact us for more information on 01706 521188.

Other Links & Information

A blog post from Kingspan which is titled 'How to fit spotlights, recessed lights and downlights in insulation' can be found at this link: CLICK HERE.